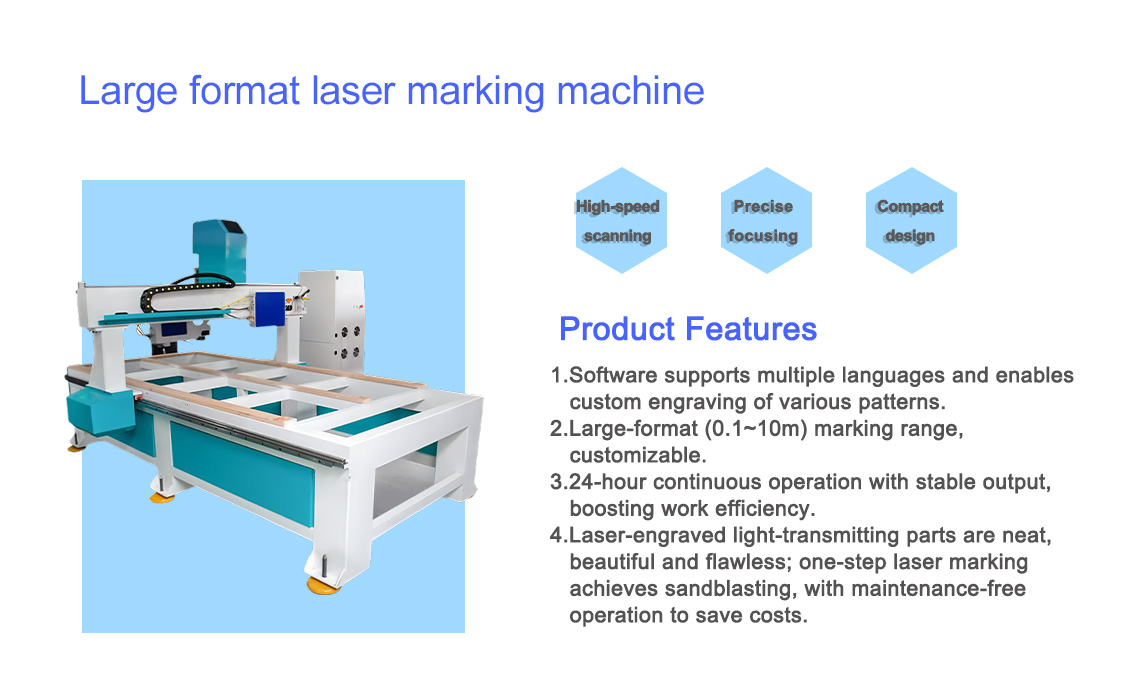

Description

Smart mirror laser grinding machine is an innovative equipment for smart mirror production and manufacturing, specially designed to solve the complexity and high cost problems in traditional production process. It integrates three important processes of smart mirror grinding, mirror/glass drilling and mirror film removal through advanced laser etching technology, which greatly improves the efficiency of production enterprises and significantly reduces the equipment acquisition cost.

Key Features & Benefits

✔ All-in-One Processing – Integrates grinding, drilling & film removal in single operation

✔ Massive Working Area – Customizable marking range from 0.1 to 10 meters

✔ 24/7 Production Ready – Industrial-grade stability for continuous operation

✔ Flawless Results – Produces uniform matte finishes without physical contact

✔ Smart Software – Multi-language support with intuitive pattern design interface

✔ Cost-Effective – Maintenance-free operation reduces production expenses

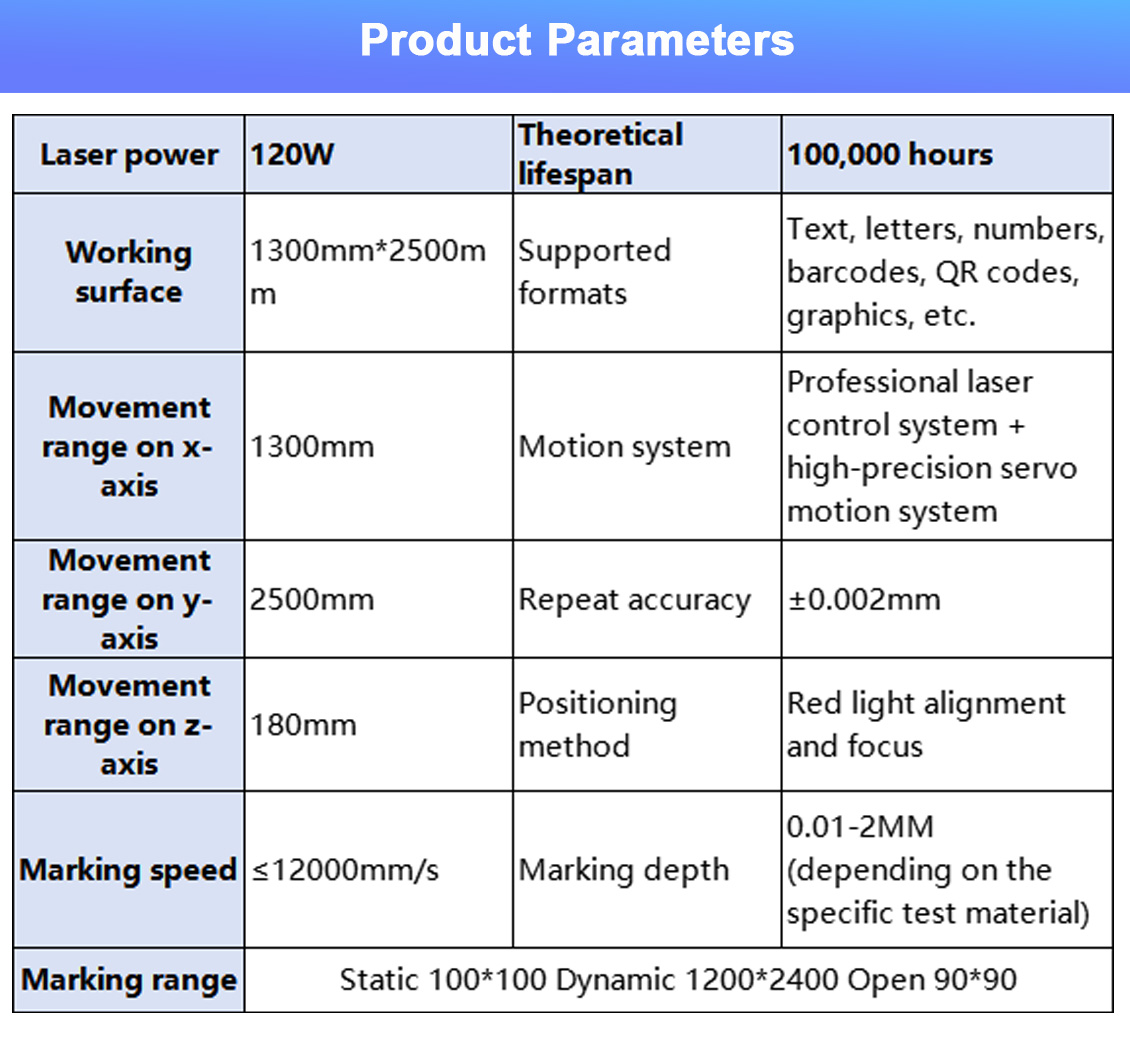

Technical Specifications

-

Processing Range: Customizable up to 10m

-

Laser Type: High-precision CO2/Fiber (configurable)

-

Operation Mode: Fully automated

-

Applications: Smart mirrors, glass, ceramics, fabrics

-

Production Capacity: 24/7 continuous operation

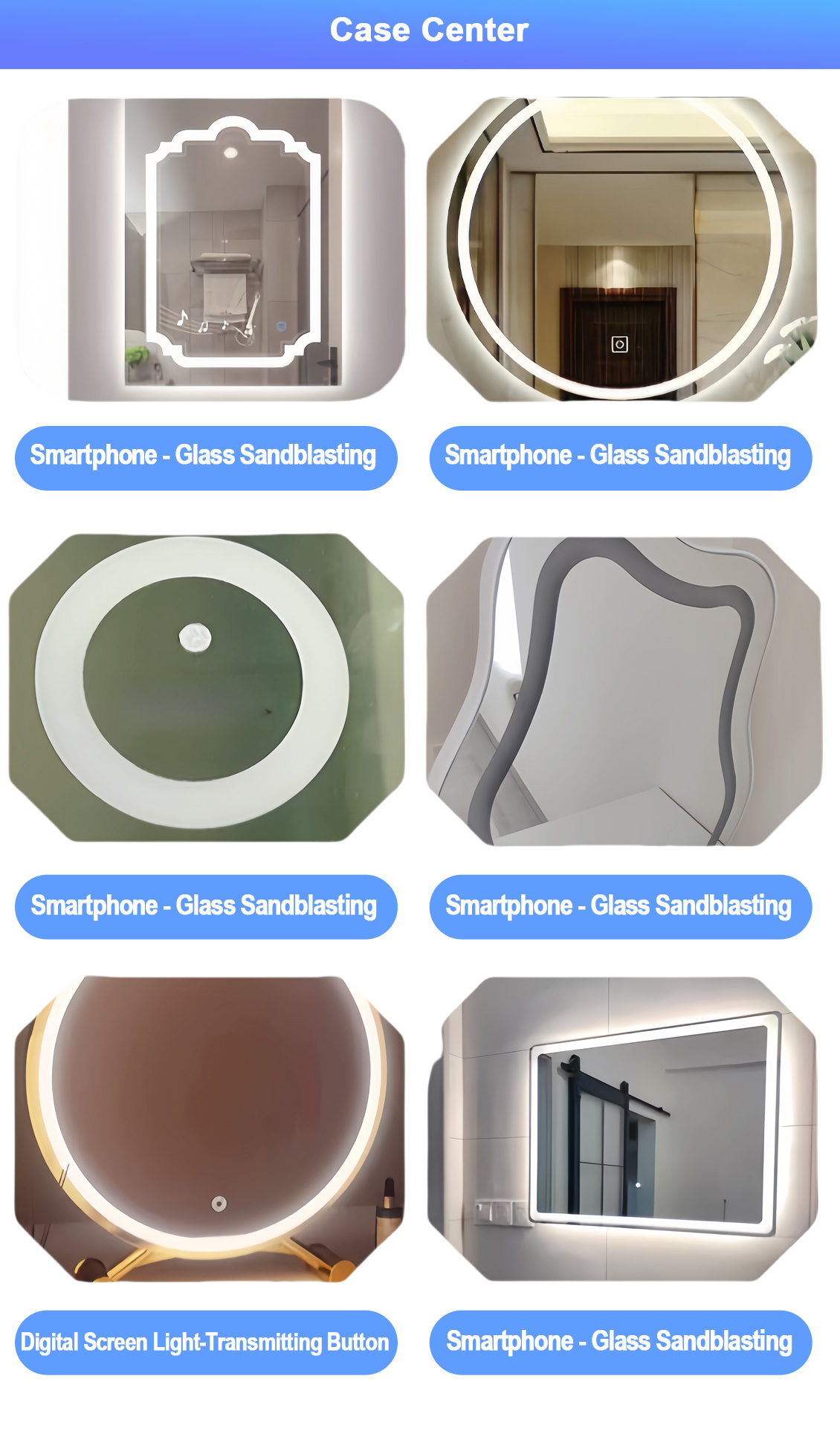

Industry Applications

-

Smart Mirror Manufacturing: Precise light-transmitting area creation

-

Architectural Glass: Decorative patterns on large glass panels

-

Ceramic Tile Production: Custom designs for interior decoration

-

Fabric Processing: Delicate marking without material damage

-

Packaging Industry: High-volume paper/cardboard marking

Why Choose Our Laser System?

✅ 80% Cost Reduction vs traditional sandblasting/drilling methods

✅ Perfect Repeatability – Digital precision eliminates human error

✅ Eco-Friendly Process – No consumables or hazardous materials

✅ Plug-and-Play Integration – Works with existing production lines

Transform your production with our all-in-one laser solution – Where innovation meets industrial efficiency!

Reviews

There are no reviews yet.