Description

Product Description

Laser spot welding machine can weld all precious metals and their alloys without any filler or soldering material. Robust, invisible repairs of high quality can be achieved within a short time: cleaning porous surfaces of platinum and gold cast parts, repair of claws, or processing of ring sizes.The comparatively narrow processing window for highly reflective materials such as silver and gold, requires a perfect and consistent beam quality in order to keep the weld quality constant.

Product Parameters

| Model | Magic Box |

| Laser Type | 1064nm YAG Laser |

| Beam Diameter | 0.2-2.0mm |

| Pulse Width | 0.1-10ms |

| Frequency | 1.0~10.0Hz Continuously Adjustable |

| Maximum Laser Pulse Energy | 40J |

| Host Power Consumption | ≤1.5KW |

| Cooling System | Convective air cooling |

| Pump Source | Xenon lamp |

| Aiming and Positioning | Microscope + HD digital CCD camera system |

| Operating Mode | Touch Control |

| Display Touch Screen | 10X high quality colorful Digital CCD |

| Operating Language | English, Chinese |

| Electrical Connection Values | AC220V ± 5%, 50HZ / 60HZ |

| Machine Dimension | Ø295mm x H282mm |

| Wooden Package Dimension | 40x45x48CM |

| Machine Net Weight | 13.5KG |

| Operating Environmental Temperature | ≤45℃ |

| Humidity | < 90% non-condensing |

| Application | Welding and repairing all kinds of jewelry and metal parts |

Product Features

1. The laser spot welding machine has high precision (0.1-2mm spot size) welding method, and the laser beam is very thin.

2. The laser speed is fast, and the frequency can reach 50HZ.

3. Jewelry, spectacle frames, molds, teeth need laser welding, and the welding is beautiful joint.

4. Laser spot welding machine is a new product, buying this product can help you win the advanced market.

5. The power supply we produce has great advantages in price and after-sales service.

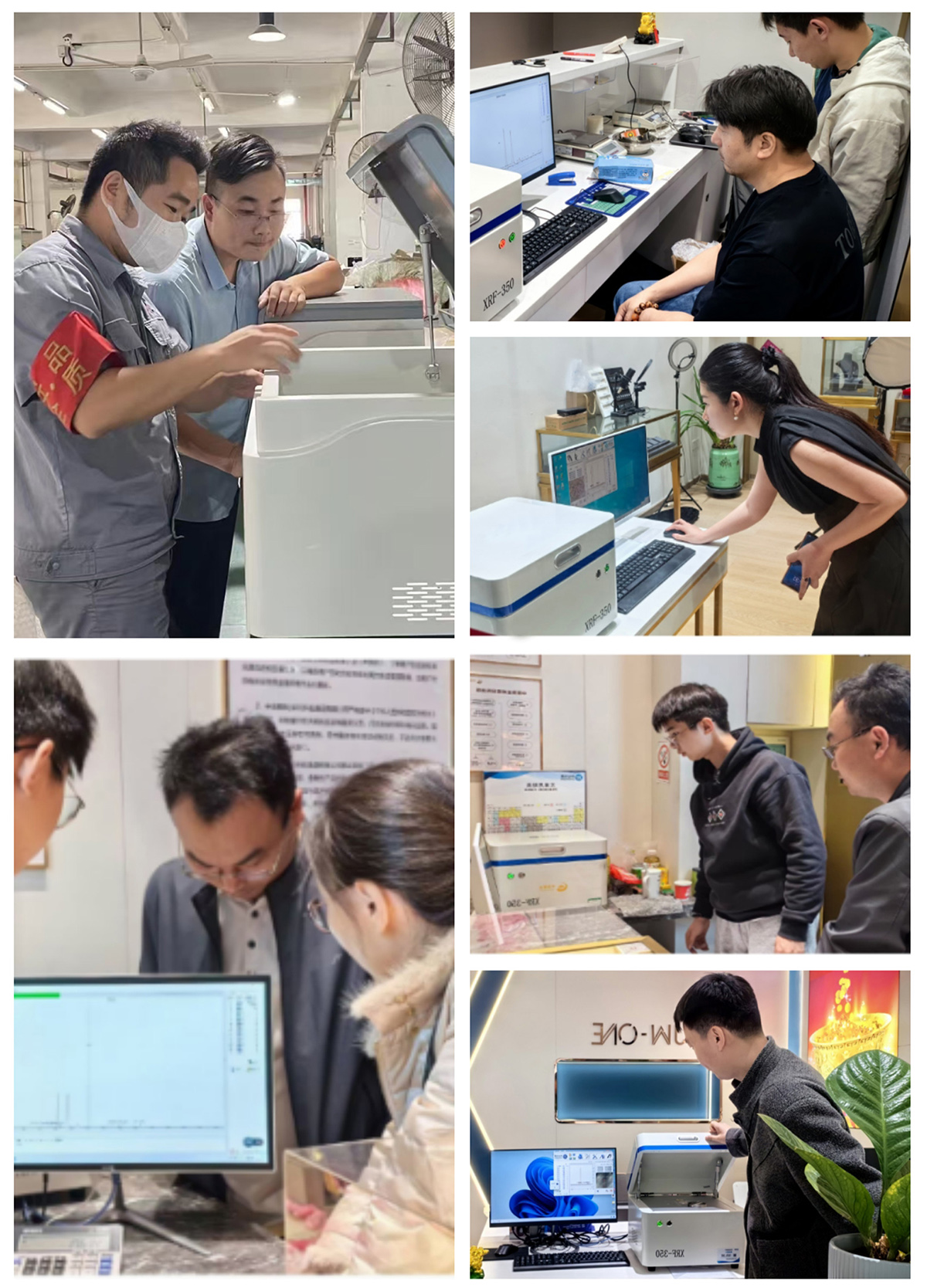

6. Engineer onsite service.

Reviews

There are no reviews yet.