Description

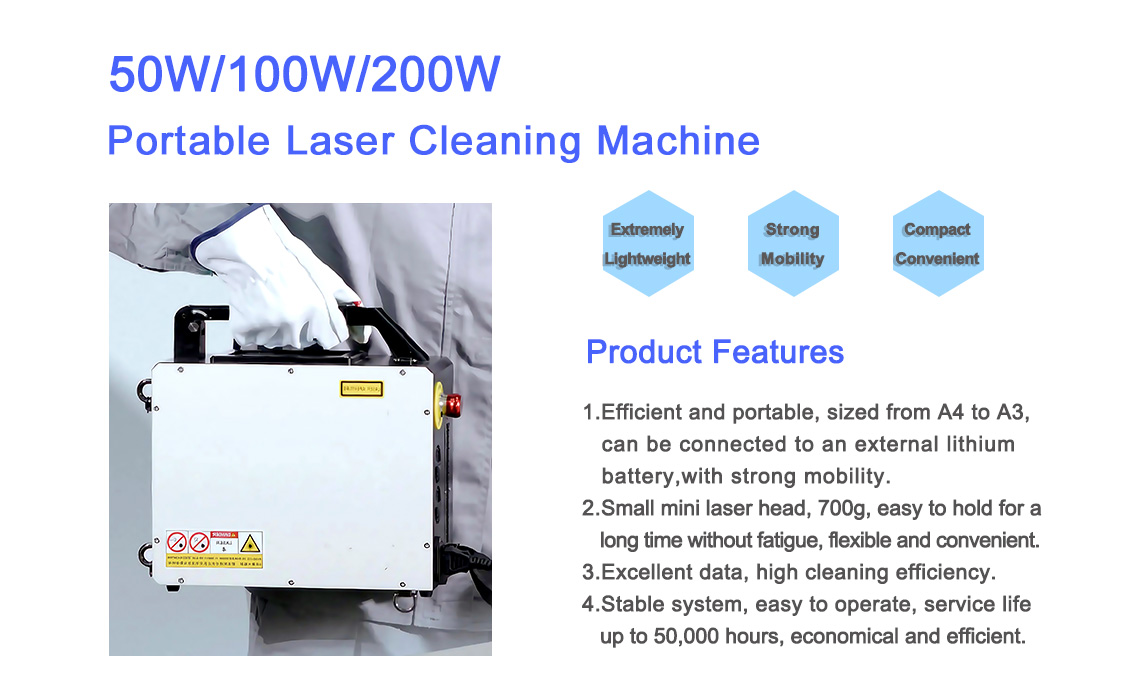

50W Backpack Laser Cleaning Machine – Professional Rust Removal Solution

The 50W Backpack Laser Cleaning Machine is a portable, high-efficiency solution for rust, paint, and coating removal. Combining an advanced integrated control system with precision fiber laser technology, it delivers superior cleaning performance for industrial applications.

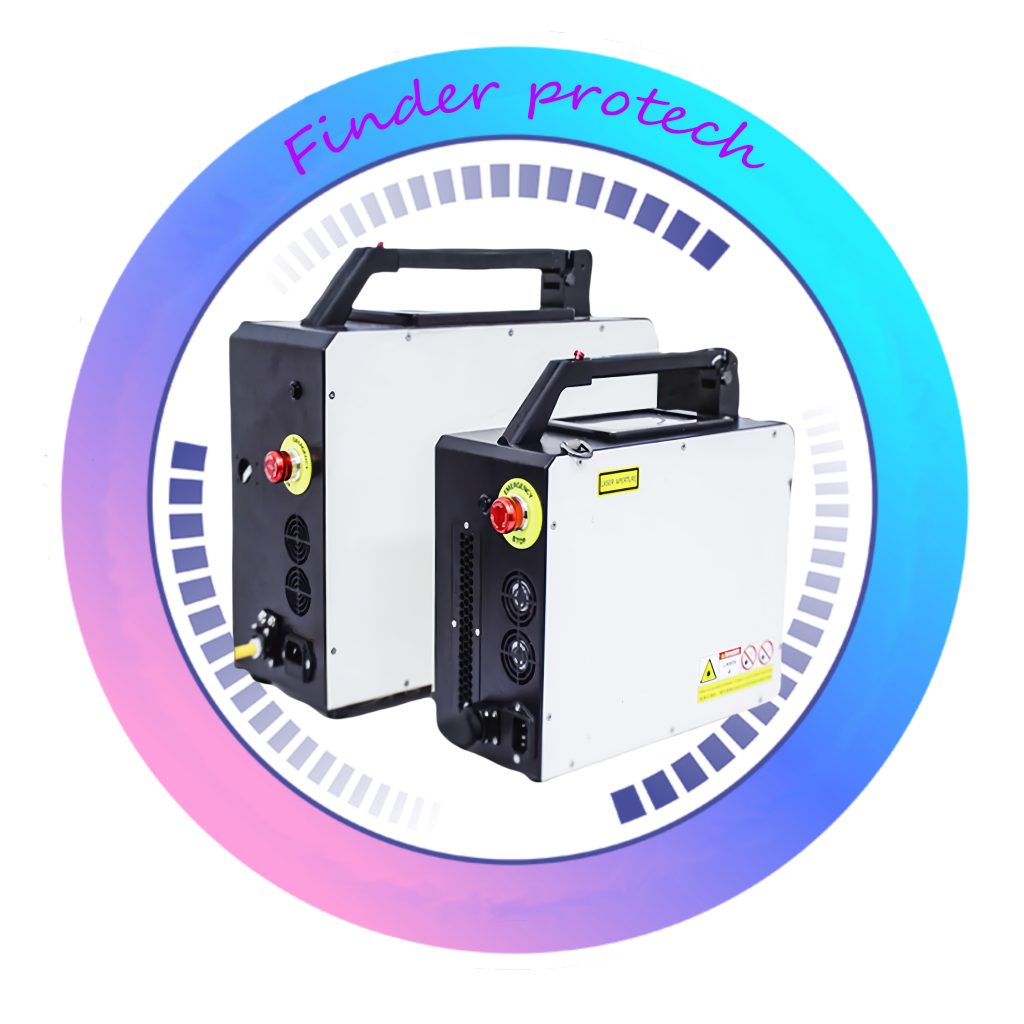

| Model | FD-PH50 | FD-PH100 | FD-PH200 |

| Laser Power | 50W | 100W | 200W |

| Cooling Way | Air Cooling | Air Cooling | Air cooling |

| Laser Wavelength | 1064nm | 1064nm | 1064±5nm |

| Pulse Energy | 0.8mJ | 1mJ | 1.5mJ |

| Fiber Length | 3m | 3m | 3m |

| Dimension | 32*13*28cm | 38*16*28cm | 45*16.3*33.9cm |

| Weight | 8kg | 12.5kg | 18kg |

| Options | Portable | Portable | Portable |

| Beam width | 10-100mm | 10-100mm | 10-100mm |

| Temperature | 5-40℃ | 5-40℃ | 5-40℃ |

| Voltage | Single Phase AC 220V,50/60HZ | Single Phase AC 220V,50/60HZ | Single Phase AC 220V,50/60HZ |

| Laser head weight(Kg) | <1.5 | <1.5 | <1.5 |

| Laser head scanning range(mm*mm) | 100*100 | 100*100 | 100*100 |

| Laser head focus length(mm) | 160, 254 | 160, 254 | 160, 254 |

Key Features:

✔ Multi-Use Design – Supports handheld, shoulder-back, and desktop operation

✔ Portable & Compact – Lightweight chassis with vertical handling for easy transport

✔ Power Flexibility – Works with external batteries for electricity-free environments

✔ Zero Consumables – One-time investment with no additional costs

✔ Wide Applications – Ideal for urban graffiti, weld cleaning, high-altitude work, and precision workshops

Why Choose This Machine?

-

Higher cleanliness & lower operational costs vs. traditional methods

-

Suitable for complex shapes and fine positioning

-

Durable 3-layer export packaging ensures safe delivery

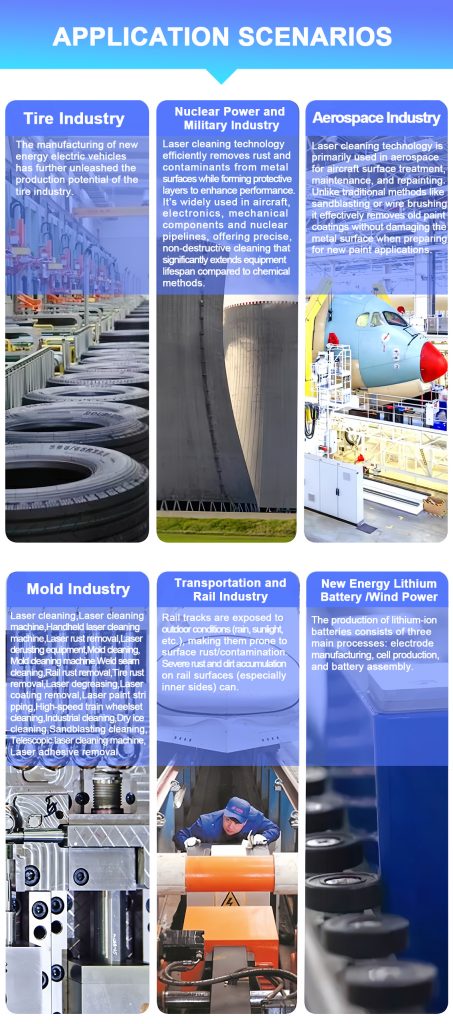

Perfect for: Metal maintenance, automotive, aerospace, and restoration projects!

Reviews

There are no reviews yet.